TPO roofing may look familiar if you have ever seen a brightly colored roof. TPO roofing is a common type of roof for large commercial buildings. It offers the highest energy savings of any single-ply membrane roofing. TPO is a single-ply roofing membrane which covers the roof’s surface.

It is common to connect TPO roofing with the stark, bright and amazing white rooftops that you have seen in commercial and industrial parks all across the country. It’s probably TPO, a common single-ply roofing material used in commercial roofing designs.

What is single-ply roofing and TPO roofing?

TPO (thermoplastic polefin), and PVC (polyvinylchloride) are single-ply thermoplastic roofing membranes with heat-welded seams. Both are “cool” roofing materials that can help you save money on your energy bills. The installation process is similar. Chemical formulae are what make the difference between these two materials. Both materials are made to conform to roof movement. However, PVC is more chemical resistant and flexible than TPO. TPO is more economical and has better thermal expansion.

Single-Ply Membranes:

Single-ply membranes can be made from both synthetic and rubber materials. These membranes can be attached to a flat roofing surface by being either mechanically fastened, ballasted to a roof or affixed with insulation.

One-ply is a well-known type of commercial material. You might not be aware that there are two types single-ply membranes available. They can be tailored to both commercial and residential budgets. These types are:

- Thermoplastic Polyolefins (TPO).

- Ethylene Propylene Diene Terpolymer (EPDM)

These single-ply membranes have different material and energy efficiency. They also differ in how they are installed.

TPO Roofing

TPO stands for Thermoplastic Polyester. It is a single-ply membrane made up of synthetic components and reinforced by a fabric scrim. This membrane provides enhanced and greater performance. It is made up of various rubber types, which are often a mixture of polypropylene or ethylene-propylene.

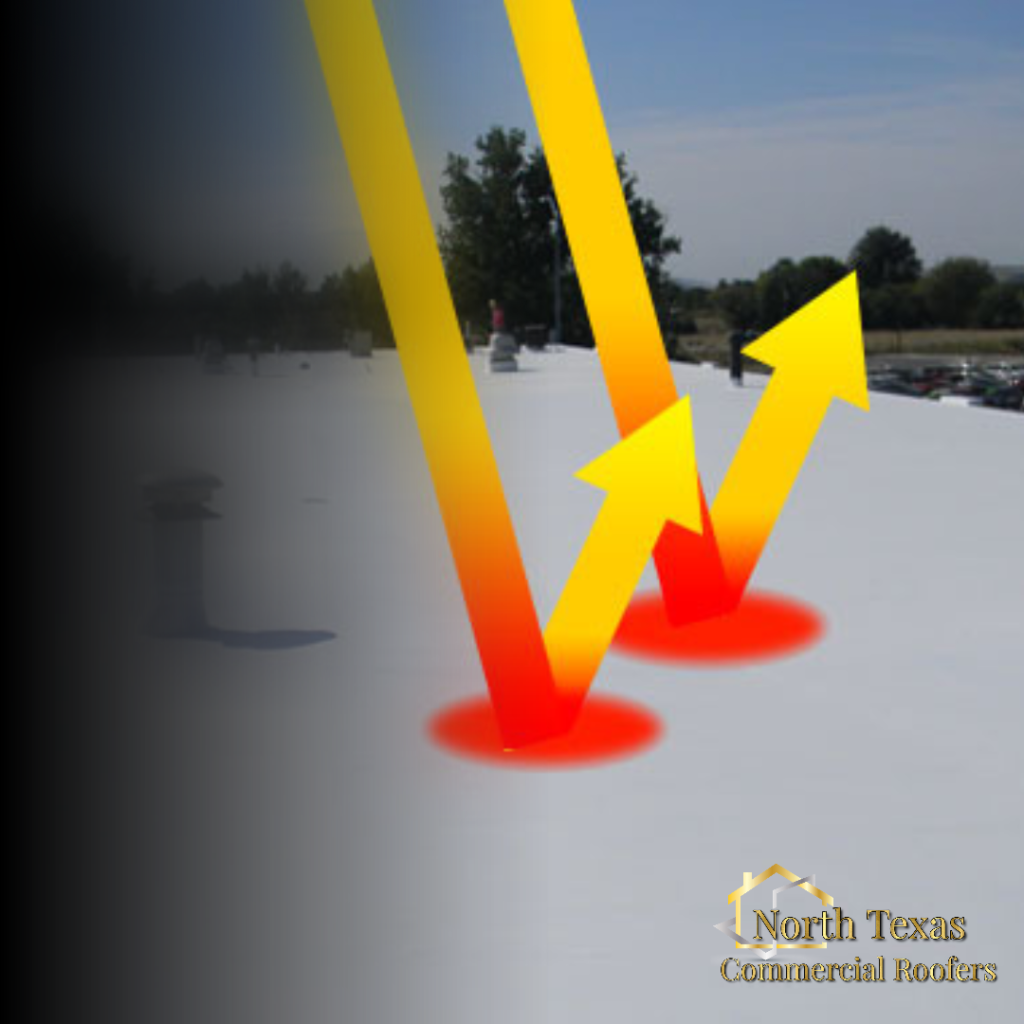

TPO is a popular choice for commercial roofing systems, especially when covering flat roofs. TPO is highly sought-after for its natural reflectivity to absorb ultraviolet radiation (UV), which allows it to save energy and reduce utility costs.

The membranes are made by the manufacturer in sheets. They can be cut to any width you like, including 10, 12, or 20 feet. After the sheets are cut, rolled and assembled, they are distributed to the commercial roofing facility that requested them.

How to Install a TPO Roofing

After removing the substrate or the surface to which the TPO membrane will be attached, prepare and clean it. Then, install the insulation. There are many options for insulation.

Polyiso (or Polyisocyanurate) is one of the most commonly used insulation types for roofing. Although it can be expensive, it has a high R value rating. This is the measurement of a material’s resistance to heat flow. This rating indicates that insulation is strong enough to resist heat.

EPS or Expanded polystyrene is an insulation that has the highest R-value and can be used for roofing, floor, and wall insulation. It is water-resistant and can be used when there is contact with the ground.

(XPS), Extruded polystyrene This insulation is distinguished by its colors, which can be either pink, blue or green. Its cost and performance are comparable to EPS and Polyiso. It’s semipermeable and has a perm rate of 1. The perm rating measures the flow rate of water through a given area of material. A roofing material with a high perm rating will have more water vapor than other materials. A score of 1 or lower indicates that less water vapor passes through roofing materials.

TPO Attachment/Adherence

TPO membranes can be mechanically fastened to cover boards or attached using an adhesive. After the membrane is rolled, the seams are joined using a hot-air gun.

TPO Roofing costs

When it comes to single-ply material costs and installation, there are many factors to be aware of. Although single-ply materials are relatively inexpensive, it is important to consider the cost of getting the best material for a fair price. These are some of the things you should consider to find a cost-effective solution.

- Roof condition

- Size of roof

- Roof access

- Selection of Insulation

- Membrane selection

- Installation options

- Roof protrusions/penetrations

- Warranty options

- TPO Benefits

Single-ply membrane roofing can last between 10-20 years if it is properly maintained and installed. Single-ply roofing systems also offer other benefits, including:

- Insulation options – Single-ply roofing systems do not provide insulation. Commercial roofing consumers have many options for insulation their commercial roofs.

- You have many options for installing a single-ply roofing. You can attach it to the roof deck or fasten it with adhesives. You can even heat weld it in difficult areas like chimneys, protrusions and projections.

- TPO Roofing Resists Corrosion- TPO is immune to corrosion and disintegration from contact with different materials. It’s also resistant to mildew, algae, and doesn’t require pressure washing. This makes it easy to maintain.

Fire-rated, Class A – Both EPDM and TPO membranes are fire-resistant. The manufacturer may add fire retardant chemicals during the manufacturing process.

Reflective and penetrable – TPO roofing is typically white and very reflective. Contrary to TPO, EDPM is often dark due to the membrane’s natural colors and its ability to retain the sun’s rays. To Learn more about TPO Roofing System Give us a call today.